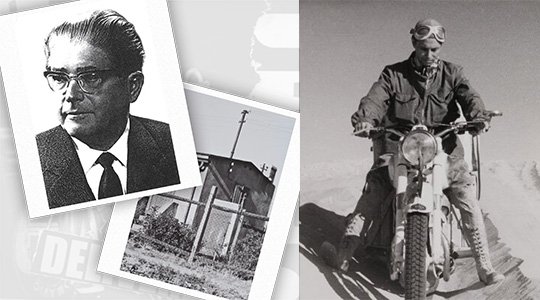

1926: The beginnings

The company was founded in 1926 by Philipp M. Winter, who began by making protective eyewear in a small workshop. In the 1960's, Rainer Winter, the founder's son, took over the company and began to expand its product line. In addition to sunglasses, uvex began making ski goggles, safety glasses, and other types of protective eyewear. uvex also began to expand its operations internationally, opening subsidiaries in other countries.

Today, uvex is one of the world's leading manufacturers of safety equipment, committed to innovation and quality, designing products that meet the highest standards of safety and performance.

UV400 - Comprehensive protection against harmful UV rays

The name UVEX comes from UltraViolet EXcluded. Just like our skin, the sun can damage our eyes when spending time outdoors which is why it’s important to protect them and the surrounding skin. The EN 166/170 standard specifies safety eyewear made with a polycarbonate lens should provide UV protection up to 380 nm, and most industrial safety eyewear does comply with this standard. However, the World Health Organisation (WHO) and latest scientific studies state that this level of protection is insufficient and recommend safety eyewear lenses provide UV protection up to 400 nm.

This level provides comprehensive protection against harmful UV rays, filtering out 100% of UVA and UVB radiation up to 400 nm. All uvex polycarbonate safety eyewear incorporates UV400 (filtering UV up to 400mn) so you can rest assured that your employees eyes are protected whether you choose clear or tinted lenses from uvex.

Unrivalled lens coatings that outperform anything on the market

The quality of the lens coating is a critical element of safety eyewear. Developed in our state-of-the-art manufacturing facilities in Fürth, Bavaria, our lens coating technology exemplifies the pinnacle of German engineering, ensuring that our coatings remain permanent even after repeated cleaning. This level of durability offers exceptional value for money, and our unique advanced coatings provide superior scratch-resistance, anti-fog properties, and chemical-resistance, ensuring clear vision and long-lasting performance.

We have formulated our own coating chemistry which is the cornerstone to uvex’s coating performance success. Unlike conventional dip coating processes, the unique uvex process applies different coatings to either side of the lens allowing each to optimally perform. Once the coating has been applied, we finalise the process by curing the coating onto the lens creating a bond for sustained performance for the lifetime of the lens.

Crystal clear vision – optical class 1 quality

Over the decades, uvex has become synonymous with high-quality safety eyewear, combining cutting-edge technology with unparalleled comfort and style. Innovative materials, state-of-the-art manufacturing processes and our exacting standards that measure functionality, ergonomics and durability, ensure the highest quality safety eyewear from uvex.

All lenses are manufactured in-house with 100% visual inspection throughout the production process. This ensures all uvex safety eyewear is certified to optical class 1, delivering edge-to-edge crystal clear vision, with no dilution of clarity at the periphery for distortion-free vision.

Recognising everyone is an individual – One size doesn’t fit all

We understand that achieving the perfect fit is crucial for optimal safety and comfort. That's why we offer our comprehensive eyewear fit programme, designed to ensure that every individual finds the right solution for their unique needs. Head and facial shapes all differ requiring a range of eyewear from which employees can select.

Our programme takes into account the employee’s features, work environment and personal requirements e.g. compatibility with other PPE. With uvex, you can trust that our high-quality safety eyewear solutions are specifically designed to meet the demands of your workplace.