Standards and directives for safety eyewear

All uvex industrial safety eyewear undergoes stringent testing in our own test centre. As well as satisfying national and international safety standards, every uvex product must fulfil the exacting uvex standards that measure functionality, ergonomics, durability and wearer comfort.

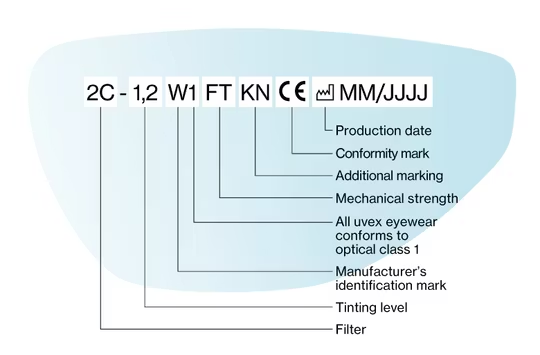

Marking on lenses in accordance with EN 166

| 2 | UV protection filter (EN 170) |

| 2C/3 | UV protection filter with colour recognition (EN 170) |

| 4 | IR protection filter (EN 171) |

| 5 | Sunglare filter for industrial use (EN 172) |

| 6 | Sunglare filter with infrared requirement |

| AR | 1.2 (Light transmittance 74.4–100%) |

| Clear | 1.2 (Light transmittance 74.4–100%) |

| Amber | 1.2 (Light transmittance 74.4–100%) |

| CBR65 | 1.4 (Light transmittance 58.1–80%) |

| Silver mirror 53% | 1.7 (Light transmittance 43.2–58.1%) |

| CBR23 | 2.5 (Light transmittance 17.8–29.1%) |

| Grey 23% | 2.5 (Light transmittance 17.8–29.1%) |

| Polavision | 3.1 (Light transmittance 8–17.8%) |

| Grey 14% | 3.1 (Light transmittance 8–17.8%) |

| Silver mirror 12% | 3.1 (Light transmittance 8–17.8%) |

| None | Minimum robustness (filters only) |

| S | Increased robustness |

| F | Low-energy impact (45 m/s or 162 km/h) |

| B | Medium-energy impact (120 m/s or 432 km/h) |

| A | High-energy impact (190 m/s or 684 km/h) |

| T | Tested under extreme temperatures (-5°C/+55°C) |

| K | Surface resistance to damage by small particles in accordance with EN 168 (scratch-resistance) |

| N | Resistance to fogging in accordance with EN 168 |

| 8 | Protection against short-circuit electric arc |

| 9 | Protection against molten metal and hot solids |

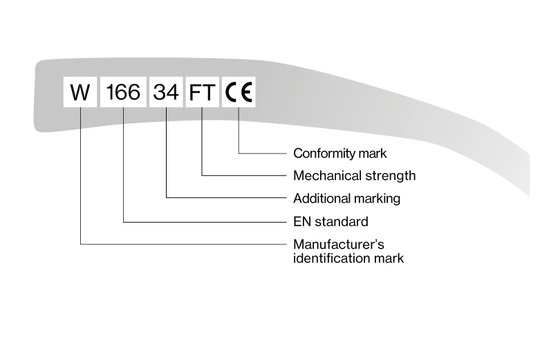

Marking on frame in accordance with EN 166

| None | General use |

| 3 | Protection against liquids (drops and splashes) |

| 4 | Protection against large dust particles with a grain size of > 5 μm |

| 5 | Protection against gases, vapours, smoke, fumes and fine dust particles with a grain size of < 5 μm |

| 8 | Protection against short-circuit electric arc |

| 9 | Protection against molten metal and hot solids |

| None | Minimum robustness (filters only) |

| S | Increased robustness |

| F | Low-energy impact (45 m/s or 162 km/h) |

| B | Medium-energy impact (120 m/s or 432 km/h) |

| A | High-energy impact (190 m/s or 684 km/h) |

| T | Tested under extreme temperatures (-5°C/+55°C) |

DIN EN 169 – Filters for welding and related techniques

In relation to special product requirements for eye protection, the EN 169 standard defines protection levels and transmittance requirements for lens filters intended to protect employees during:

- light flame cutting

- hard soldering

- welding

- arc gouging

- plasma cutting

Labelling and protection levels for welding filters in accordance with standard EN 169

Welding filters must be permanently marked on the edge. The first number refers to the protection class of the safety eyewear. Depending on the procedure, higher electrical currents require higher protection classes in accordance with DIN EN 169.

| Level of protection | Use | Gas used | Flow rate (l/h) |

| 1.7 | Protection against scattered rays for welding assistants | - | - |

| 3 | Lightweight oxyacetylene cutting | - | - |

| 4 | Welding and braze welding | Acetylene | < 70 |

| 5 | Welding and braze welding Oxyacetylene cutting | Acetylene Oxygen | 70 - 200 900 - 2,000 |

| 6 | Welding and braze welding Oxyacetylene cutting | Acetylene Oxygen | 200 - 800 2,000 - 4,000 |

DIN EN 170 – Ultraviolet filters

As part of the standards for special product requirements, standard DIN EN 170 defines the protection levels and transmittance requirements for ultraviolet filters. If the lens of the eye is exposed to ultraviolet light for too long, it can lose its transparency, potentially leading to visual impairment or vision loss. Safety eyewear lenses in accordance with EN 170 therefore meet performance requirements to protect the eye from ultraviolet radiation during hazardous activities.

Unlike welding filters in accordance with EN 169, the UV filters are not suitable for looking at electrical arcs, either directly or indirectly.

DIN EN 171 – Infrared protection filter

The effect of infrared radiation on human tissue can be harmful. Since it is not immediately noticeable, infrared radiation can increase the risk of permanent eye damage, such as cataracts.

Levels of infrared protection and recommendations for use according to EN 171

| 4-1.7 | average temperature of the radiation source up to 1090°C* |

| 4-2 | average temperature of the radiation source up to 1110°C (forges) |

| 4-3 | average temperature of the radiation source 1190°C (glass blowing)* |

| 4-4 | average temperature of the radiation source 1290°C (foundries) |

| 4-5 | average temperature of the radiation source 1390°C (steel foundries)* |

| 4-6 | average temperature of the radiation source 1510°C (iron foundries) |

* available in the uvex portfolio

DIN EN 172 – Sun glare filters for industrial use

DIN EN 172 is a special standard for personal eye protection and describes the required physical properties of filters used to reduce sun glare in industrial use. These properties include, for example, mechanical and optical characteristics and requirements of the sun glare filters.

To use the sun glare filters in industrial use, the general requirements for personal eye protection in accordance with DIN EN 166 must also be fulfilled. Depending on the area of use, sun glare filters in accordance with DIN EN 172 can be used either as filters in spectacles or as individual filters.

Thanks to innovative technologies, uvex sun glare filters in accordance with DIN EN 172 offer perfect colour perception combined with optimal protection.