Case studies

uvex safety have helped a number of businesses overcome challenges to provide appropriate protection for their employees, allowing them to go home safely. Read our product testimonials and case studies to see how our innovative designs and technologies have protected people in a range of work environments.

uvex footwear achieves cost savings and improves employee wellbeing

A major automotive manufacturer faced a significant challenge with their choice of safety footwear. They were experiencing high replacement rates, with each employee going through 3–4 pairs per year. With 7,000 employees on-site, this amounted to a considerable annual expenditure, prompting the company to explore more sustainable and cost-effective alternatives.

uvex gloves and glasses help welding specialist protect people and planet

For welding companies, health and safety is an absolute priority. This particular company are specialists in architectural and structural metalwork, covering all aspects of metal fabrication and installation, and require high-quality PPE to keep their employees safe.Sustainability is another key focus for this organisation. The business is committed to caring for the environment at both a local and a global level, employing the most environmentally efficient techniques and materials.

uvex 1 safety shoes combine total comfort, longevity, safety and grip at Pegler Yorkshire

Pegler employees had previously been wearing a well-known high street safety boot brand which they found uncomfortable and unreliable in the oily, greasy manufacturing conditions in which employees work. Pegler's Safety, Health & Environment Manager Rob Forrestall had previous experience of, and trust in, uvex’s products. Based on this, Rob invited uvex in to try and resolve the company’s footwear issues.

Needlestick glove with fluid injection resistance

A Supervisor suffered a serious injury when a hydraulic hose burst and injected hydraulic oil into his hand. The Supervisor needed emergency surgery in hospital to treat the injury. Read how HexArmor gloves with SuperFabric® are helping to protect against high-pressure fluid injection injuries.

Suited and booted in uvex 1 business safety footwear

uvex’s unique multipurpose protective footwear goes from factory to office at AMP Automation. Alan is a long-time fan of uvex products, the workforce having previously worn either uvex black brogue safety shoes, or one other brand. But once he came across the uvex 1 business shoe, he was hooked.

uvex phynomic wet safety glove brings great relief from dermatitis

A precision-engineering production company in South East England found the uvex phynomic wet safety glove brought relief from dermatitis for one of their machine setters. Barry, a CNC machinist, had been suffering badly with painful contact dermatitis brought on by exposure to industrial lubrication as part of his job.

uvex 1 reduces foot ache by 53%, increases grip by 35% and improves comfort by 38%

Late last year, uvex was invited in to a well-known car manufacturer’s factory to conduct a footwear trial, which was making modifications to the production line ready for a new car model. Although the production line workers had been using antifatigue matting since 2001 to try to make the workers’ life more comfortable, the matting had been identified as the cause for some safety incidence.

uvex gives water company employees absolute protection from sharps

uvex have worked with a national water company to provide suitable protection for their employees against needlestick injuries. The operational area of the company covers both urban and rural locations where staff are regularly exposed to discarded hypodermic needles and sharps.

HexArmor gloves guard against needlestick injury

Scot Grant, a private ambulance technician, suffered a possibly life-threatening needlestick injury from a used injection needle while at work. He now carries a set of HexArmor PointGuard® Ultra 4041 needlestick-resistant gloves in his search vest to protect his hands in future.

uvex i-works removes the risk of eye injury at Trelleborg

TSS wanted an eye protection product that was comfortable and that fit the bill in every way. They trialled a range of safety spectacles from uvex and two other well-known brands, after which Craig surveyed the wearers and then scored their feedback.

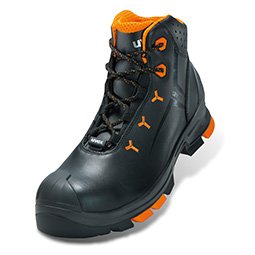

uvex 1 and Heckel MACSOLE® improve safety and delight wearers

Safety and comfort have been greatly improved by the use of uvex 1 and Heckel Macsole® FXH at a large UK automotive components manufacturer based in the Midlands, where 95% of its 1,100 employees require safety footwear. The £multi-million turnover company has been on its present site for around 130 years and has five manufacturing sites in the UK, plus 125 across the world.

uvex phynomic gloves eliminate skin irritation

uvex helped to overcome a construction Site Manager's skin allergy caused by the wearing of gloves at Rydon Construction. Darren Cooper is Site Manager of Rydon Construction, a property development and maintenance company based in East Sussex that employs over 700 people.

uvex removes Denby Pottery’s PPE concerns

uvex goes the extra mile for Denby Pottery, helping with employee safety, comfort and quality. Gary Pearson, Denby’s UK Group Health and Safety Manager, has been with the company for nine years and has been a customer of uvex for 15-20 years. He is responsible for health and safety implementation and management throughout the company.

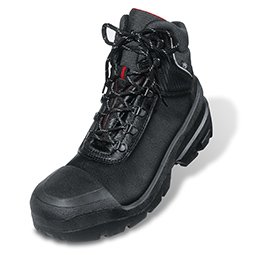

uvex solves boot problem for Hochtief Murphy on Crossrail Project

When Hochtief Murphy Joint Venture (HMJV) discovered the safety boots it had issued to its workers on the £14bn Crossrail project were not only uncomfortable but were falling apart after a couple of months’ use, the company turned to uvex for a solution.

Dorset Police choose uvex pheos sunglare safety spectacles

Dorset police force were responsible for policing the international sailing and water sports events at the 2012 Olympic games, where several hundred specialist officers on the 50-plus boats (RIBs) were provided with a full range of personal protective equipment (PPE), including uvex pheos protective sunglasses and uvex hi-com disposable earplugs.

Young Worldskills competitor reviews uvex products

Ben Tullett, a senior Aircraft Technician at RAF Odiham, has been chosen as part of the UK team at the prestigious global competition WorldSkills 2013, the largest international skills competition in the world, which will take place from 2 to 7 July in Leipzig, Germany.

Lanes Group case study

Lanes had been experiencing a high level of wastage of the safety glasses they had been using, because the spectacles continually misted up and easily became scratched, as they did not have anti-mist or anti-scratch coatings. Now, uvex safety spectacles last 16x longer than safety specs previously used and wearers find a novel method of storing them.

Wates Group case study

The Wates Group hoped that eye injuries would be a thing of the past after it introduced a mandatory eye protection policy that required everyone to carry eyewear and use it when work conditions demanded. In the five years that followed, 73 workers on Wates sites suffered eye injuries despite the policy, making it clear that just supplying the equipment was not enough.

Got a question about one of our products? Fill in our quick form and we will get back to you

Contact us

Sign up to our newsletter to receive information about our latest products, services and other interesting highlights

Sign up now