uvex gives water company employees absolute protection from sharps

“The HexArmor® gloves provide a higher level of dexterity than previously experienced, and together with the increased protection, have improved staff confidence. We are always looking for higher quality products enabling our employees to carry out their roles safely.” – a senior Health, Safety and Wellbeing (HSW) adviser for a national water company.

The operational area of the organisation covers both urban and rural locations. With a large number of widespread assets, its staff are regularly exposed to discarded hypodermic needles and sharps. These are sometimes thrown over fences into sites, left in picnic areas around reservoirs, or more commonly dropped into valve chambers or hydrant chambers in footpaths.

Collection and disposal are relatively easy when the sharps are in open areas, but when they are within chambers or valve boxes, this can be more of a challenge. Wherever possible, the company’s staff are trained to use tongs, tweezers, or scoops to pick up sharps, rather than a gloved hand. However, where this isn’t possible, and gloves are required, these must provide a good degree of dexterity to ensure that wearers keep them on. If gloves are uncomfortable, or lack movement and flexibility, they do not get worn.

The retrieval of hypodermic needles or drug-related paraphernalia is reported as an incident on the company’s safety reporting system. Where gloves are worn, this is done by any of the organisation’s frontline operational staff in waste and/or potable water, and by countryside ranger staff who are trained in the retrieval and disposal of sharps. The team had previously used a well-known competitor’s product which lacked flexibility and dexterity. Staff often took them off because they found it difficult to pick up needles while wearing them, because of their ridged design.

Why HexArmor® Gloves?

uvex worked with the company both on-site and at conferences to educate them on the American National Standards Institute (ANSI) standard and to demonstrate HexArmor®’s SuperFabric®, which provides proven, industry-leading needlestick resistance while retaining dexterity.

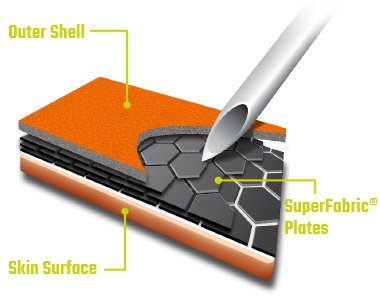

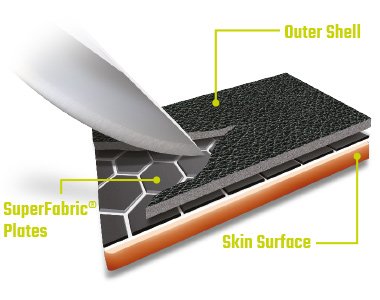

SuperFabric® is a breathable, durable and lightweight fabric, reinforced with an overlay of tiny armour plates. The geometric pattern of the guard plates on polyester provides optimum resistance to high cut, fine puncture and needlestick hazards. HexArmor® gloves work by layering SuperFabric® materials over each other, blocking and deflecting needle hazards or trapping them in the small gaps between the layers.

The company’s HSW adviser explained that when looking at the organisation’s needs for safety gloves, they have a protective clothing user group, comprising representatives from all business areas and their trade union. They engage with their colleagues who undertake tasks that require hand protection and obtain the appropriate glove through consultation, trials and a formal written feedback risk assessment.

The water company received several “very good” product demonstrations from uvex on the HexArmor® products. Following the initial demonstrations, uvex gave workers samples for field trials. Feedback from wearers ensured they obtained the correct product for their needs.

The company has approved products from HexArmor® because of their needlestick protection, the range available for various applications, and the dexterity of the gloves. The gloves that they are now using are the HexArmor® SharpsMaster HV® 7082 and the HexArmor® Hercules® NSR 3041.

Industry leading needle resistance

The SharpsMaster HV® 7082 is extremely resistant to needles and cuts at the highest level and has a nitrile coating for extra protection against needles, oil, liquids and grease. It is made with three layers of SuperFabric® material to provide even greater resistance to needlestick hazards.

Industrial ultra cut and puncture resistance

The Hercules® NSR 3041 is a heavy duty, fully cut-resistant safety gauntlet glove. The two layers of SuperFabric® provide optimum blade cut-resistance to protect against sharp metals, wires, woods and glass, as well as giving the best possible protection against cut hazards to the hand, fingers and wrists.

How did HexArmor® gloves solve the company’s problems?

“The HexArmor® gloves provide a higher level of dexterity than previously experienced, and together with the increased protection have improved staff confidence. We are always looking for higher quality products enabling our employees to carry out their roles safely,” the company’s HSW adviser affirmed.

“uvex together with HexArmor® has provided a very good product range with local support that fully understands our needs and how these requirements can be best met. It is good to know there is a proactive company out there, that we can approach to discuss such needs.”

The adviser reports that the provision of items for trial has been well received by wearers, who have given positive feedback. “Users within the business regard the products as being leading-edge and of good quality,” he states.

Based on their current experiences and their relationship with the HexArmor® range of products, plus uvex’s excellent support, the company is looking at future collaboration with uvex when new or innovative hand protection becomes available, or when they have a specific need based on their industry requirements.

“It is good to know there is a proactive company we can approach to discuss such needs,” concludes the H&S professional.