Choosing the right respiratory protection

Choosing the right respiratory protection is essential for ensuring the safety of the respective wearer and is a process that requires the utmost care. In order to choose the filtering respirator that meets your requirements, be sure to observe the following points:

- The type, composition and concentration of the hazardous substances must be provided/known (note the CAS number and OEL).

- After determining the protection class required (FFP1, FFP2 or FFP3), the table below can be used to select a respirator model that meets the requirements of the respective working conditions.

- If further PPE is required, this must be compatible. uvex respirators are ideal for use in combination with uvex safety spectacles — see our compatibility table.

- Respiratory protective devices are not suitable for people with beards, sideburns or deep scars near the respirator sealing lines as these prevent a secure fit.

- Masks marked “NR” should not be used for more than eight hours. Masks marked “R” may be used for up to 24 hours but must be cleaned after each period of use. Masks should be replaced without delay if the breathing resistance becomes noticeably higher.

- If a half-mask with gas filters is required for the workspace, please note that the uvex respirator models do not offer adequate protection.

- In the UK, we also have the Standard Assigned Protection Factor (APF) to help employers comply with the Control of Substances Hazardous to Health Regulations 2002 (COSHH), aimed at controlling exposure to and protecting workers health when working with chemicals. The APF is an estimate of how much protection a respirator provides. When fitted (face fit test) and worn correctly an FFP1 respirator should reduce exposure to airborne particles by a factor of 4, an FFP2 by a factor of 10 and an FFP3 by a factor of 20.

Selection based on working conditions

| Brief periods of use or lighter activities at normal ambient temperatures | ||

| Protection class | Folding mask (with or without valve) | Cup-style mask (without or without valve) |

| FFP1 | 8763100, 8763110 | 8732100, 8732110 |

| FFP2 | 8733200,8733210 | 8732200, 8732210, 8762220 |

| FFP3 | 8763310 | 8762310, 8762312 |

| Long periods of wear or hard, strenuous activities at increased ambient temperatures | ||

| Protection class | Folding mask (with valve) | Cup-style mask (with valve) |

| FFP1 | 8763110 | 8732210 |

| FFP2 | 8733210 | 8732210, 8762220 |

| FFP3 | 8763310 | 8762310, 8762312 |

| With activated carbon layer to protect against unpleasant odours | ||

| Protection class | Folding mask (with valve) | Cup-style mask (with valve) |

| FFP1 | - | - |

| FFP2 | 8763220 | 8732220 |

| FFP3 | - | - |

Got a question about one of our products? Fill in our quick form and we will get back to you

Contact us

Which protection factor suits your needs?

Particle filters are divided into three classes

| FFP1 Respirators | FFP2 Respirators | FFP2 carbon layered Respirators | FFP3 Respirators | |

| Assigned Protection Factor (APF) | APF 4 | APF 10 | APF 10 | APF 20 |

| Typical applications | Low level fine dust/oil or water based mists (hand sanding, drilling and cutting) | Moderate level fine dust/oil or water based mists (plastering, cement, sanding and wood dust) | Options for metal fume, ozone and nuisance levels of certain gases and vapours | Higher level fine dust/oil or water based mists (hazardous pharmaceutical powders, biological agents and fibres) |

APF = Assigned Protection Factor

FFP1 Identified by blue valve lettering

FFP2 Identified by orange valve lettering

FFP3 Identified by grey valve lettering

When correctly used by a wearer who has passed a face fit test, an FFP1 respirator should reduce exposure to airborne particles by a factor of 4, an FFP2 by a factor of 10 and an FFP3 by a factor of 20.

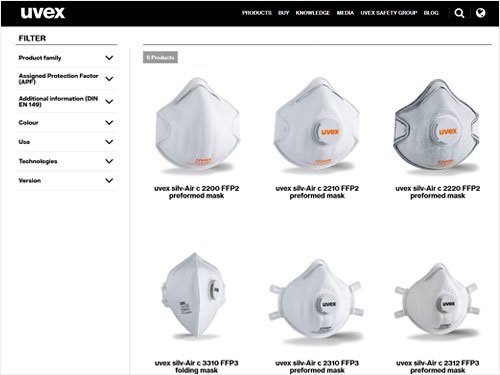

uvex silv-Air c range

How to fit a flatfold P2 mask

How to fit a preformed mask